A backorder arises when demand surpasses available supply, preventing immediate customer order fulfillment. This can stem from factors like sudden demand spikes, supply chain delays, or production issues. Efficient backorder management is vital for customer satisfaction and streamlined supply chain operations. Organizations commonly utilize predictive analytics and advanced inventory strategies to minimize backorder impact and enhance overall supply chain performance.

The Challenge

Backorder Challenges are from unpredictable demand, supplier delays, and production issues. Fluctuating customer needs and supply chain disruptions can deplete inventory, leading to unfulfilled orders.

Managing backorders is critical for customer satisfaction and brand loyalty. Organizations need proactive strategies to address backorder challenges.

This involves leveraging technology for demand insights and optimizing inventory. Resilient supplier relationships are crucial for managing backorders effectively.

Managing backorders isn’t just about resolving disruptions; it’s about fortifying the supply chain for future uncertainties. The goal is to ensure efficient operations and meet customer expectations with resilience and excellence.

What did PredictEasy do...

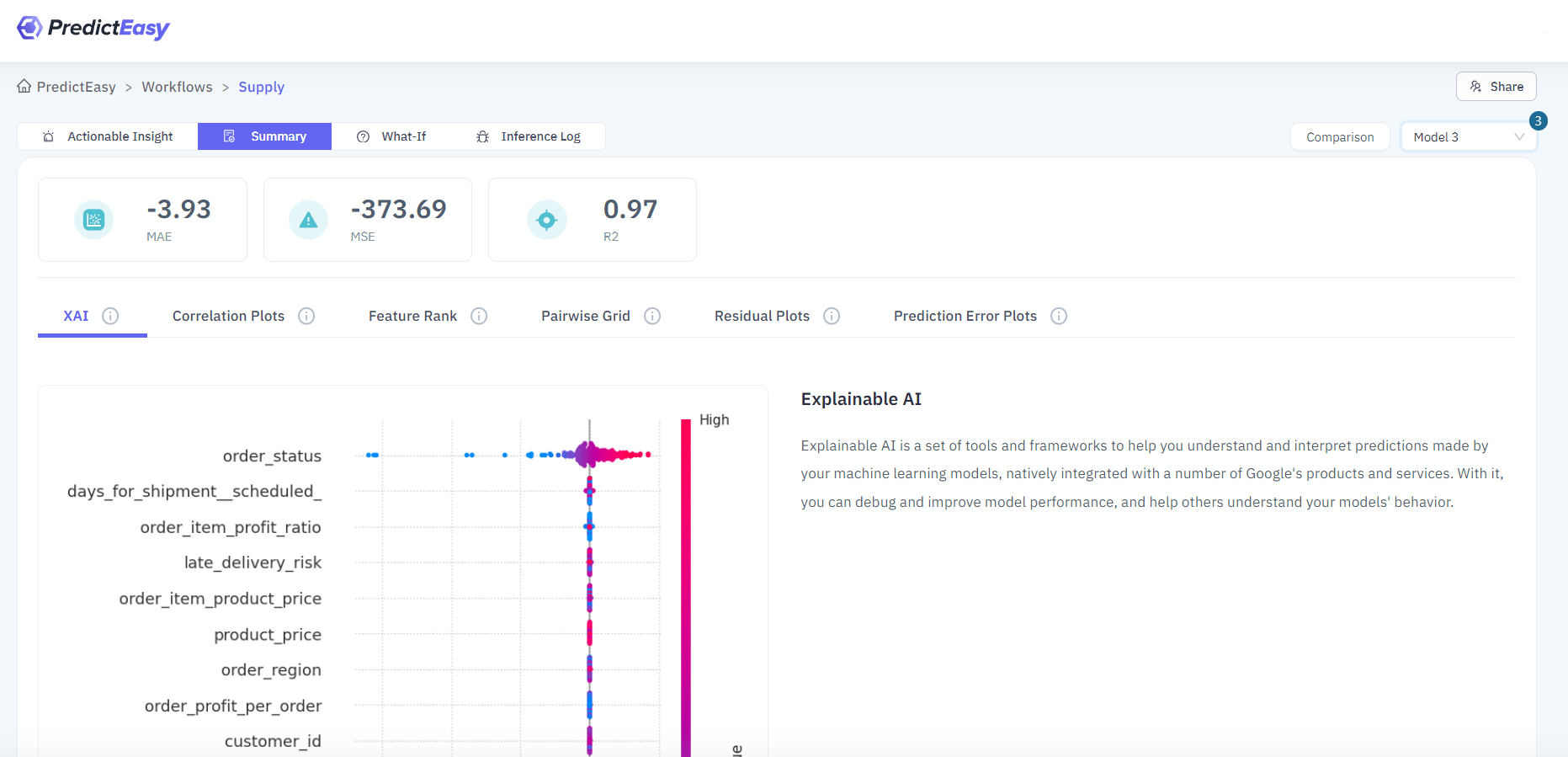

PredictEasy streamlines backorder management through a systematic approach, beginning with the collection of historical records, real-time inventory levels, demand forecasts, and external factors and advanced analytics and predictive modeling, seamlessly integrating information to transform backorder analysis with its data analytics capabilities.

The subsequent step involves model training, during which PredictEasy fine-tunes its model using collected data to accurately predict potential backorders, demonstrating a deep understanding of complex supply chain dynamics.

The final phase assesses the model’s performance using metrics such as accuracy, F1 score, precision, and recall, showcasing PredictEasy’s proficiency in delivering precise insights.

The What-if simulator is a dynamic tool that enables users to adjust inputs in real-time, generating corresponding probability values. This functionality guides informed decision-making on backorders.

The Results

-

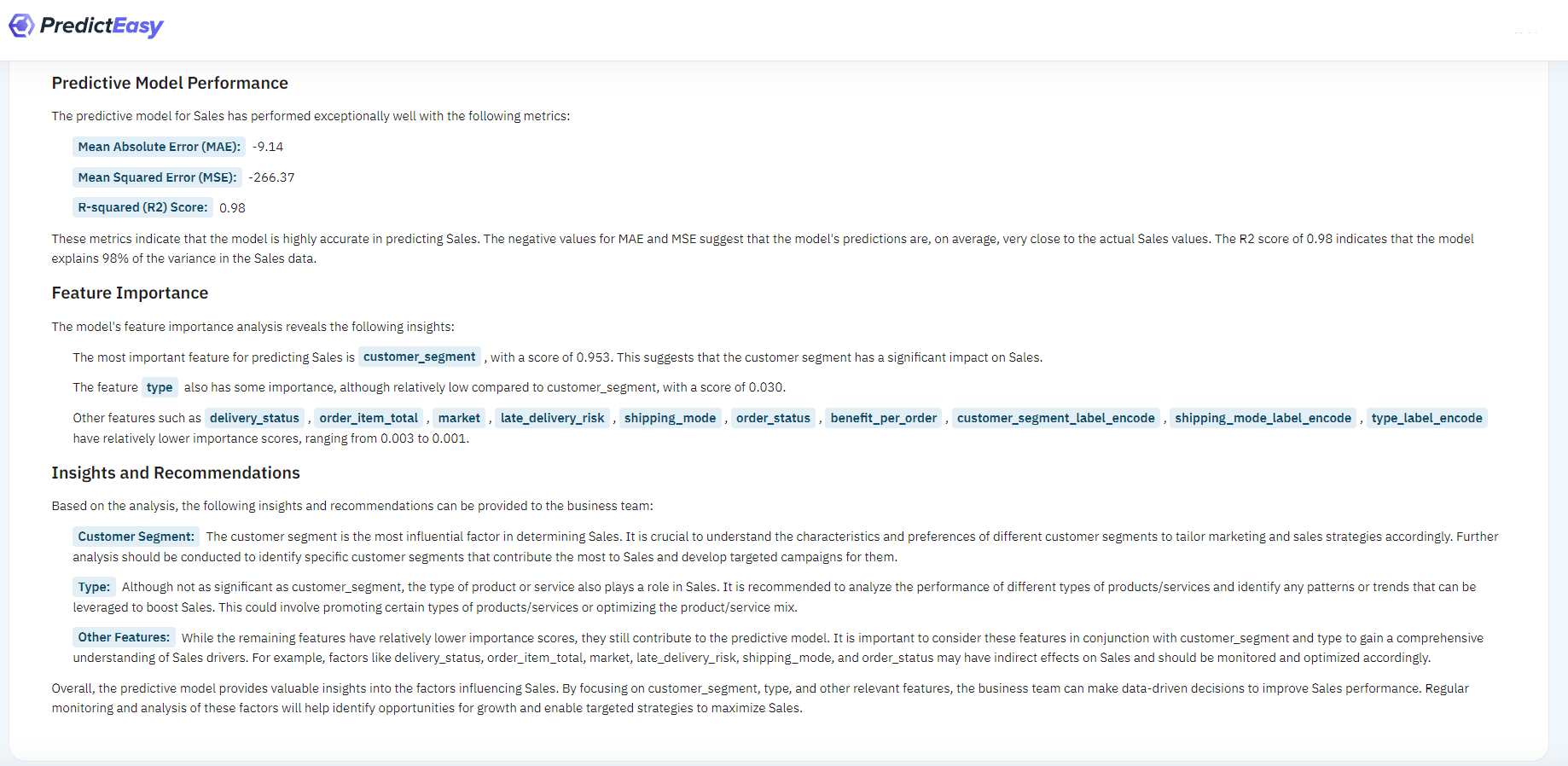

Accuracy and Prevention: PredictEasy demonstrates impressive accuracy in identifying and preventing backorders, highlighting its potential to significantly enhance both supply chain efficiency and customer satisfaction.

SHAP Value Analysis: The SHAP value analysis, graphically represented, uncovers crucial factors influencing backorder predictions. Features like exponential smoothing forecasts, sales data for various periods, and lead time emerge as key contributors, with elevated values indicating a higher likelihood of increased backorders.

AI-powered Recommendations: PredictEasy's AI-powered recommendations revolutionize how organizations address backorder prevention. Grounded in artificial intelligence, these recommendations offer practical and actionable insights, providing organizations with effective strategies for proactive issue resolution.

Proactive Issue Resolution: Leveraging PredictEasy's insights allows organizations to proactively address influential factors contributing to backorders. This strategic approach results in a tangible reduction in backorders and an overall enhancement of supply chain performance.

Efficient Backorder Management: The shift towards efficient backorder management and operational excellence is facilitated by PredictEasy's AI-driven recommendations. Organizations can strategically implement these insights to optimize their supply chain processes.

Transformative Role: In conclusion, PredictEasy plays a transformative role in supply chain management by delivering precise insights and actionable recommendations. Effectively addressing backorder challenges through machine learning empowers organizations to proactively navigate issues, reduce backorders, and ultimately achieve operational excellence in their supply chain processes.